Manual Shifter Assembly: A Comprehensive Overview

Manual transmissions feature crucial parts like the clutch‚ gears‚ shafts‚ and gearbox housing‚ working in harmony for controlled vehicle operation and driver engagement.

Manual transmissions represent a foundational element in automotive engineering‚ offering a direct mechanical link between the engine and wheels. Unlike automatic systems‚ they require the driver to actively select gears using a shift knob and shift rods. This control stems from core components like the clutch‚ input shaft‚ output shaft‚ and intricate gear sets.

Understanding these systems involves recognizing the interplay of synchronizers‚ ensuring smooth gear changes‚ and the gear selector mechanism‚ dictating gear engagement. Historically‚ manual transmissions predated automatics‚ providing a robust and efficient means of power transfer. Modern advancements continue to refine these systems‚ though their fundamental principles remain consistent‚ offering a uniquely engaging driving experience.

Historical Context of Manual Shifters

Manual shifters emerged alongside the earliest automobiles‚ representing the primary method of gear selection for decades. Initially‚ these systems were considerably simpler‚ lacking the synchronizers found in modern transmissions. Early drivers required significant skill to execute smooth gear changes‚ often employing double-clutching techniques.

Throughout the 20th century‚ manual transmissions evolved‚ incorporating improvements in metallurgy and design. The development of gearbox housing and more precise gear sets enhanced reliability and efficiency. While automatics gained popularity‚ manuals retained a dedicated following‚ prized for driver control and mechanical simplicity. Today‚ despite declining market share‚ manual shifters persist‚ celebrated for their engaging driving experience and continued relevance in performance vehicles.

Core Components of a Manual Transmission

Manual transmissions fundamentally rely on interconnected components to transfer engine power to the wheels. The input shaft receives power from the clutch‚ while the output shaft delivers it to the drivetrain. A crucial intermediary is the countershaft‚ facilitating gear ratio changes.

Essential elements include the gear sets themselves‚ dictating speed and torque‚ and synchronizers‚ enabling smooth‚ clash-free gear engagement. Shift forks and shift rods‚ activated by the gear selector‚ physically move gears into position. The entire assembly is housed within a robust gearbox housing‚ protecting internal parts and providing structural integrity. These components work in precise coordination to provide controlled power delivery.

Input Shaft and its Function

The input shaft serves as the initial receiver of rotational power from the engine‚ directly connected to the clutch assembly. Its primary function is to transmit this power into the manual transmission. This shaft spins at a speed determined by engine RPM and clutch engagement.

It features splines to connect with the clutch disc and supports various gears. The input shaft’s durability is critical‚ as it withstands significant torsional stress. Proper alignment and bearing support are essential for smooth operation and longevity. It’s a foundational component‚ initiating the power transfer process within the entire drivetrain system‚ ultimately driving the vehicle.

Output Shaft and its Role

The output shaft is the final component in the manual transmission responsible for delivering rotational power to the driveshaft and subsequently‚ the wheels. Receiving power from the countershaft via gears‚ it spins at a speed determined by the selected gear ratio.

This shaft features splines to connect with the driveshaft‚ transmitting torque to propel the vehicle forward. Its robust construction is vital to handle the full load of engine power. Proper sealing prevents lubricant leakage‚ ensuring efficient operation. The output shaft’s integrity directly impacts vehicle performance and overall drivetrain reliability‚ completing the power delivery cycle.

Countershaft: The Intermediate Gear

The countershaft‚ also known as the lay shaft‚ plays a critical intermediate role within the manual transmission. Positioned between the input and output shafts‚ it receives power from the input shaft and transfers it to the output shaft through various gear pairings.

Constantly rotating when the engine is running‚ the countershaft’s gears are typically fixed to it‚ while gears on the output shaft are free to rotate. This arrangement allows for different gear ratios to be selected. Its precise alignment and smooth operation are essential for efficient power transfer and quiet operation‚ making it a fundamental component of the transmission’s functionality.

The Clutch System: Engaging and Disengaging Power

The clutch system is paramount in a manual transmission‚ serving as the vital link between the engine and the gearbox. Its primary function is to smoothly engage and disengage power transmission‚ allowing for gear changes and vehicle starting/stopping.

This system relies on the interaction of the clutch disc and pressure plate. When engaged‚ the pressure plate clamps the disc against the engine flywheel‚ transferring rotational force. Depressing the clutch pedal disengages this connection‚ interrupting power flow. Proper operation of the clutch pedal and its associated linkage is crucial for seamless shifting and preventing wear.

Clutch Disc and Pressure Plate Mechanics

The clutch disc‚ a friction material sandwiched between the engine flywheel and pressure plate‚ is central to power transfer. It features splines connecting to the transmission’s input shaft. The pressure plate‚ spring-loaded‚ exerts force clamping the disc against the flywheel‚ creating friction and transmitting engine power.

When the clutch pedal is released‚ the pressure plate firmly secures the disc. Depressing the pedal disengages this clamping force via a release bearing‚ allowing the disc to spin freely. This interruption enables gear changes. Wear on the friction material of the clutch disc diminishes its grip‚ leading to slippage and requiring replacement.

Clutch Pedal and Linkage Operation

The clutch pedal initiates the disengagement process‚ connecting to a linkage system – either cable or hydraulic – that actuates the release bearing. Depressing the pedal pulls on this linkage‚ pushing the release bearing against the clutch pressure plate. This action overcomes the spring pressure‚ disengaging the clutch disc from the flywheel.

Hydraulic systems utilize fluid pressure for smoother‚ more consistent operation‚ while cable systems offer a direct mechanical connection. Proper adjustment of the linkage is crucial for complete clutch disengagement and preventing dragging. Worn or damaged components within the linkage can cause incomplete disengagement‚ leading to shifting difficulties.

Gearbox Housing and Internal Structure

The gearbox housing serves as the protective enclosure for the intricate internal components of the manual transmission. Typically constructed from cast iron or aluminum‚ it provides structural rigidity and safeguards the gears‚ shafts‚ and bearings from external contaminants;

Internally‚ the housing features precisely machined bores to support the input and output shafts‚ alongside the countershaft. Ribs and strengthening features are integrated into the design to withstand the substantial stresses generated during power transmission. The housing also incorporates mounting points for the shift mechanism and seals to contain the lubricating oil‚ ensuring smooth and reliable operation.

Gear Sets and Ratios Explained

Manual transmissions utilize various gear sets to provide different torque and speed ratios. Lower gears offer increased torque for acceleration and climbing‚ while higher gears prioritize fuel efficiency at cruising speeds. Gear ratios are calculated as the number of teeth on the driven gear divided by the teeth on the driving gear.

These ratios determine the mechanical advantage‚ influencing both vehicle speed and engine load. Different gear combinations within the gearbox allow the driver to select the optimal ratio for varying driving conditions. Understanding these relationships is crucial for efficient driving and maximizing the powertrain’s potential.

Synchronizers: Ensuring Smooth Gear Changes

Synchronizers are vital components within a manual transmission‚ responsible for matching the speeds of the gears before engagement. This prevents grinding and allows for smooth‚ effortless gear changes. They achieve this by using friction to equalize rotational speeds‚ bridging the gap between the selected and current gears.

Without synchronizers‚ shifting would be jarring and damaging to the transmission. Worn synchronizers often manifest as difficulty shifting‚ particularly into specific gears‚ or a grinding noise during gear selection. Maintaining these components is essential for the longevity and drivability of the manual shifter assembly.

Shift Forks and Shift Rods: Actuating Gear Selection

Shift forks and shift rods are the mechanical intermediaries translating driver input into gear changes within the manual transmission. Shift rods connect the gear selector to the shift forks‚ which directly engage with the synchronizer sleeves to move gears. Precise movement is crucial for smooth operation.

These components work in tandem; the gear selector’s motion travels through the shift rods‚ causing the shift forks to slide the appropriate gear into engagement. Wear or misalignment in these parts can lead to imprecise shifting‚ difficulty selecting gears‚ or even a jammed transmission. Proper lubrication and inspection are vital for maintaining a functional manual shifter assembly.

The Gear Selector Mechanism

The gear selector mechanism is the driver’s interface for controlling the manual transmission. It encompasses the shift knob‚ shift boot‚ and the linkage connecting to the internal shifting components. Two primary linkage types exist: remote and direct shift. Remote shift uses a separate linkage running to the transmission‚ while direct shift connects directly.

The shift knob and boot contribute to driver feel and prevent contaminants from entering the mechanism. Precise linkage adjustment is critical for accurate gear engagement. A well-maintained selector ensures smooth‚ reliable gear changes‚ enhancing the driving experience and preventing internal damage within the manual shifter assembly.

Remote vs. Direct Shift Linkage

Remote shift linkage systems utilize a separate connecting rod and associated hardware to transmit driver input to the manual transmission. This design allows for greater flexibility in shifter placement within the vehicle cabin. Conversely‚ direct shift linkage establishes a more immediate connection‚ mounting the shifter directly onto the transmission itself.

Direct shift generally offers a more precise and responsive feel‚ minimizing play and ensuring accurate gear selection. However‚ it limits shifter positioning options. Remote linkages‚ while potentially less precise‚ provide design freedom. Proper adjustment and maintenance are crucial for both systems to prevent binding or imprecise shifting within the shifter assembly.

Shift Knob and Boot Considerations

The shift knob‚ beyond aesthetics‚ significantly impacts the driver’s tactile experience. Weight‚ shape‚ and material influence shift feel and comfort. Heavier knobs can offer a more substantial connection‚ while ergonomic designs enhance grip. The shift boot‚ typically constructed from leather or synthetic materials‚ serves a crucial functional role.

It prevents debris and unwanted elements from entering the transmission‚ protecting internal components. Furthermore‚ the boot contributes to cabin sound insulation and temperature regulation. Proper fit is essential; a loose boot can allow contaminants to enter‚ potentially damaging the shifter assembly. Regular inspection and replacement ensure optimal performance and longevity.

Hydraulic Systems in Manual Transmissions

While traditionally mechanical‚ modern manual transmissions increasingly incorporate hydraulic systems to assist with clutch operation and shift actuation. These systems utilize fluid pressure to reduce driver effort‚ particularly in heavy-duty applications. Hydraulic clutches offer smoother engagement and disengagement compared to cable-operated systems;

Furthermore‚ some advanced manual transmissions employ hydraulically assisted shifting‚ enhancing speed and precision. These systems often involve a master cylinder‚ slave cylinder‚ and fluid lines. Maintaining proper hydraulic fluid levels and inspecting for leaks are crucial for reliable operation. Contamination can compromise system performance‚ leading to shifting difficulties.

Troubleshooting Common Shifter Assembly Issues

Sticking gears and difficult shifting often stem from worn synchronizers‚ low or contaminated transmission fluid‚ or a misadjusted clutch. Inspecting the clutch pedal and linkage for proper operation is essential. Worn synchronizers cause grinding noises during gear changes‚ indicating a need for replacement. A failing clutch can manifest as slipping or difficulty engaging gears.

Diagnosing issues requires careful observation. Check for loose or damaged shift rods and forks. Internal damage‚ like bent shift forks‚ can also cause problems. Addressing these issues promptly prevents further damage and ensures safe vehicle operation. Regular maintenance and fluid changes are vital for preventing common shifter assembly failures.

Sticking Gears and Difficult Shifting

Sticking gears frequently arise from worn synchronizers failing to properly match gear speeds‚ creating resistance during shifts. Low or dirty transmission fluid exacerbates this‚ reducing lubrication and increasing friction. A misadjusted clutch can also contribute‚ preventing complete disengagement. Inspecting the shift linkage for binding or damage is crucial; worn bushings or bent rods hinder smooth operation.

Troubleshooting involves checking fluid levels and condition‚ examining the linkage for play‚ and assessing synchronizer health; Sometimes‚ simply lubricating the shift linkage resolves minor sticking. However‚ persistent issues often necessitate synchronizer replacement or clutch adjustment. Ignoring these symptoms can lead to more extensive and costly repairs.

Worn Synchronizers and Clutch Problems

Worn synchronizers manifest as grinding noises during gear changes‚ especially noticeable when shifting into higher gears. This occurs as the synchronizer’s ability to equalize gear speeds diminishes‚ causing clashing. Clutch problems‚ such as a dragging clutch‚ impede smooth shifting and can mimic synchronizer issues. A failing clutch may not fully disengage‚ making gear selection difficult.

Diagnosing requires assessing synchronizer wear during transmission disassembly. Clutch issues are identified by pedal feel‚ engagement point‚ and slippage tests. Replacing worn synchronizers and addressing clutch problems – whether adjustment or full replacement – restores proper shifting function. Ignoring these issues leads to further transmission damage and potential failure.

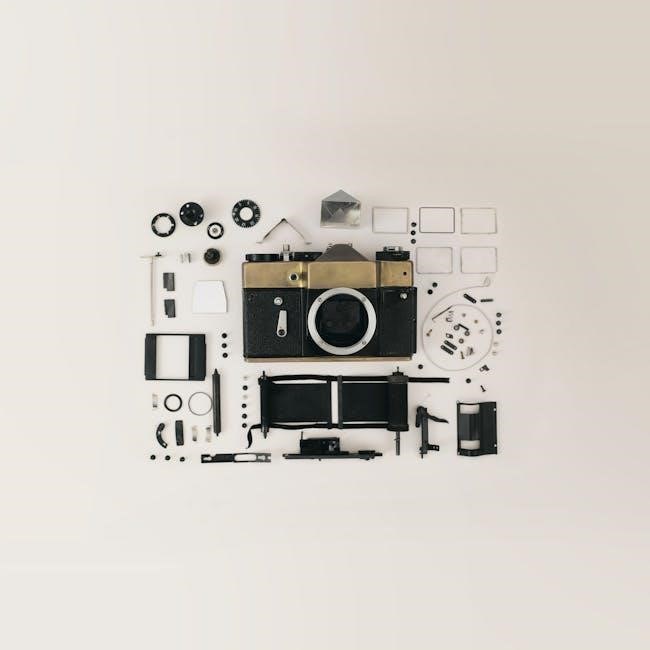

Manual Transmission Diagrams and Resources

Detailed diagrams are invaluable for understanding the intricate assembly of a manual transmission. Online resources‚ including YouTube videos‚ offer visual guides to component locations and functions‚ aiding in both repair and learning. Service manuals‚ specific to vehicle models like the Loadstar 1700‚ provide exploded views and precise part identification.

Websites dedicated to automotive repair often host transmission diagrams and troubleshooting guides. These resources showcase the relationship between the input shaft‚ output shaft‚ countershaft‚ and other key components. Accessing these materials empowers DIY mechanics and simplifies complex rebuilds‚ ensuring accurate reassembly and optimal performance.

Modern Advancements in Manual Shifter Technology

Despite the rise of automatics‚ manual shifter technology continues to evolve. Modern advancements focus on enhancing the driving experience and improving efficiency. Some systems incorporate computer-assisted gear selection‚ offering smoother shifts and rev-matching capabilities. Others explore innovative linkage designs‚ reducing friction and improving precision.

Manufacturers are also integrating features like short-throw shifters for quicker gear changes and improved shift knob ergonomics for enhanced comfort. While the fundamental principles remain‚ these refinements demonstrate a commitment to preserving the engaging nature of manual transmissions. These improvements cater to enthusiasts seeking a more connected driving experience.