What is Specially Designed Instruction (SDI)?

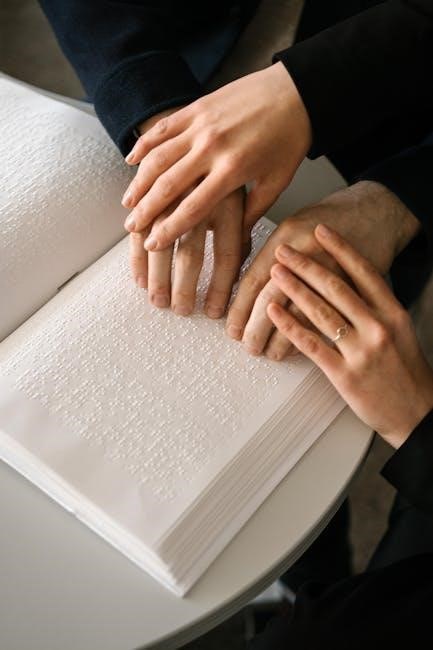

SDI, often detailed in PDF guides, adapts teaching methods to meet unique learner needs; examples showcase tailored approaches, like decoding tutorials (Moats, 2006).

Instruction sheets, and user manuals for online applications, provide sample SDI plans, guiding educators in effective, individualized support for students.

Defining SDI and its Core Principles

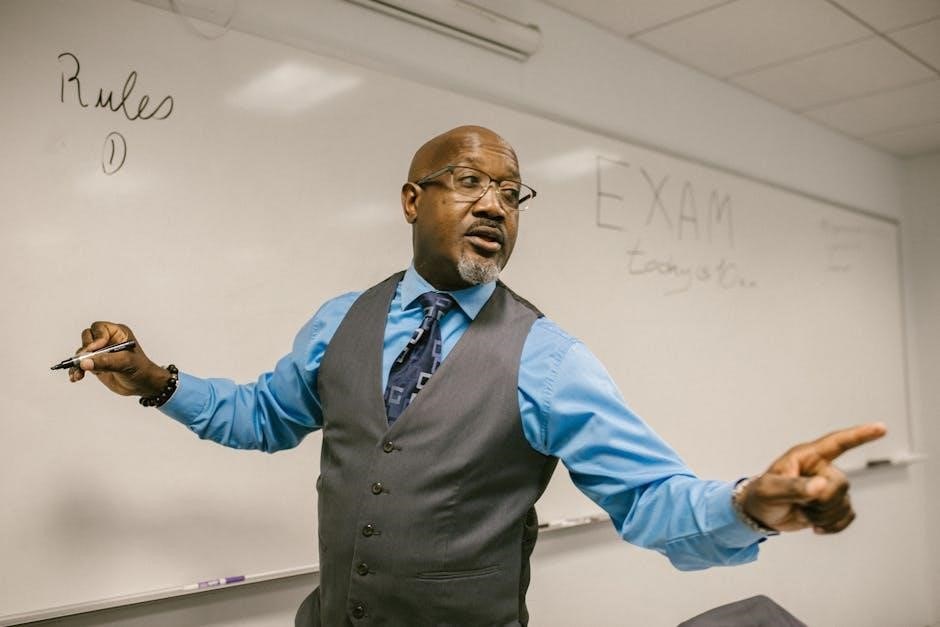

Specially Designed Instruction (SDI), often documented in PDF formats, centers on individualized learning, modifying content, methodology, or delivery. Core principles involve proactive planning, utilizing assessment data to tailor instruction, and ensuring access to the general education curriculum.

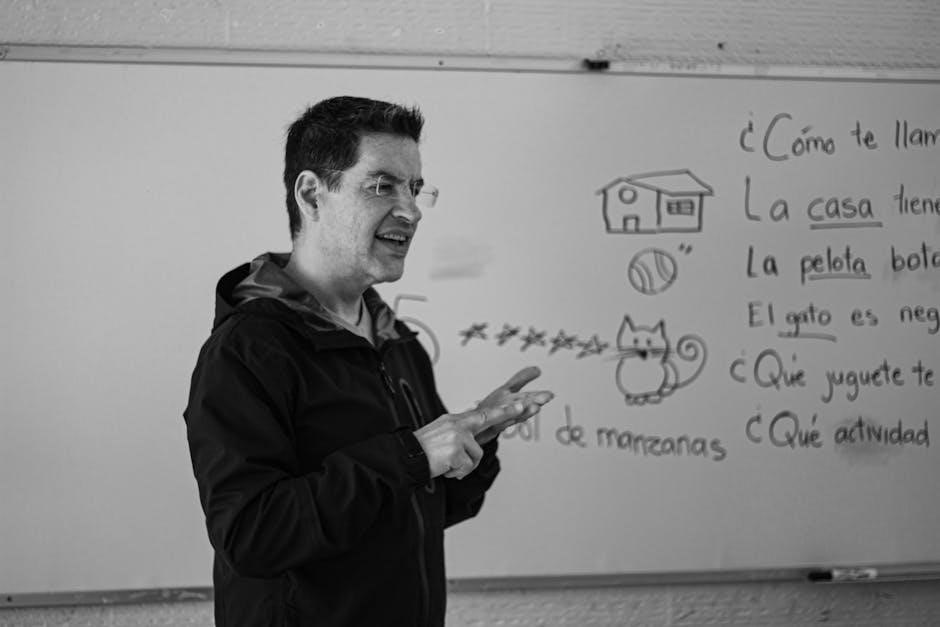

Examples, like those found in classroom language guides, emphasize adapting routines and providing clear, structured learning materials. SDI isn’t a single program, but a flexible framework; tutorials and user manuals demonstrate how to implement it. Effective SDI prioritizes student engagement and progress monitoring, referencing resources like Avas Skills Coded documentation for trainers.

It’s about creating a learning path that meets each student where they are, fostering success through targeted support.

The Legal Basis for SDI: IDEA

The Individuals with Disabilities Education Act (IDEA) mandates SDI for students requiring specialized support. IDEA ensures students with disabilities have access to a Free Appropriate Public Education (FAPE) in the Least Restrictive Environment (LRE).

SDI is a crucial component of this, legally requiring Individualized Education Programs (IEPs) to detail specific, tailored instruction. PDF resources outlining sample IEPs demonstrate how SDI is legally documented and implemented. These plans must be based on thorough assessment and address unique student needs.

IDEA emphasizes accountability, requiring educators to demonstrate the effectiveness of SDI through data-driven progress monitoring, often guided by documentation worksheets.

Identifying Students Needing SDI

PDF examples of IEPs and assessment data pinpoint students needing SDI; early identification, through research, is key for effective, tailored learning support.

The Role of IEPs in Determining SDI

IEPs are central to defining SDI; PDF examples demonstrate how individualized education programs meticulously outline specific instructional adaptations. These plans detail necessary modifications and accommodations, directly stemming from student assessment results.

The IEP serves as a legally binding document, ensuring students with disabilities receive tailored support. It’s a collaborative effort, involving educators, parents, and sometimes the student themselves. SDI components, as illustrated in sample PDF plans, are explicitly stated within the IEP, clarifying goals, methods, and evaluation criteria.

Effectively, the IEP transforms assessment data into actionable instructional strategies, guaranteeing appropriate and individualized learning experiences. It’s the cornerstone of compliant and effective special education practice.

Assessment Methods for Identifying Specific Needs

Identifying specific learning needs requires varied assessment approaches, often documented in SDI PDF examples. These methods extend beyond standardized tests, encompassing observations, curriculum-based assessments, and analysis of student work samples.

Decoding tutorials (Moats, 2006) highlight the importance of diagnostic assessments pinpointing skill deficits. Analyzing student performance informs the development of individualized SDI plans. Furthermore, formative assessments continuously monitor progress, allowing for adjustments to instruction.

Effective assessment isn’t solely about identifying weaknesses; it also reveals strengths, informing instructional strategies. Detailed assessment reports, often included as appendices in SDI guides, provide a comprehensive profile of each student’s learning needs.

Components of Effective SDI

SDI PDF examples emphasize individualized goals, modifications, and accommodations; learning materials act as a guide, providing routine and structure for both teacher and learner.

Individualized Goals and Objectives

Individualized goals are central to SDI, as demonstrated in PDF resources outlining tailored learning paths. These objectives, often documented within SDI plans, move beyond generalized curriculum expectations to address specific student needs.

For instance, a student struggling with reading comprehension might have a goal focused on improving decoding skills, supported by a teaching tutorial (Moats, 2006). PDF examples showcase how these goals are broken down into measurable objectives, like accurately reading a specific number of words per minute.

Effective SDI documentation, like the Documentation Worksheet, helps trainers outline these objectives, utilizing visuals and coded skills assessments to ensure targeted instruction. This process ensures learning is focused and impactful.

Modifications vs. Accommodations in SDI

SDI frequently employs both accommodations and modifications, often detailed in PDF guides. Accommodations change how a student learns material – for example, providing assistive technology tools – without altering the core content. PDF examples might show extended time on tests as an accommodation.

Modifications, however, change what a student is expected to learn. This could involve simplifying assignments or reducing the number of problems, as illustrated in instruction sheet examples. User manuals for online classroom applications often clarify these distinctions.

Understanding this difference is crucial for effective SDI. Documentation, like the Avas Skills Coded worksheet, helps educators determine appropriate strategies, ensuring students access and master essential learning objectives.

Examples of SDI Strategies

SDI strategies, often found in PDF resources, include graphic organizers, repeated reading, breaking down problems, and utilizing manipulatives – all tailored learning guides.

SDI for Reading Comprehension

SDI for reading comprehension, frequently detailed in PDF documents, employs targeted strategies to enhance understanding. Examples include utilizing graphic organizers to visually map concepts and relationships within texts, aiding students in processing information effectively.

Furthermore, implementing repeated reading techniques – rereading passages multiple times – improves fluency and comprehension. These tutorials, often found online, emphasize decoding instruction (Moats, 2006) as a foundational skill. Interactive instructions and online resources further support this process, offering varied approaches to cater to diverse learning styles. These methods provide a structured guide for both teachers and students, fostering a more successful reading experience.

Utilizing Graphic Organizers

SDI strategies, often illustrated in PDF examples, frequently incorporate graphic organizers to support reading comprehension. These visual tools, acting as a guide, help students structure information and identify key relationships within a text. Examples include concept maps, Venn diagrams, and story maps, each tailored to specific reading skills.

Graphic organizers facilitate a deeper understanding by prompting students to actively process information. They can be used before, during, and after reading, enhancing recall and analytical abilities. Online tutorials demonstrate how to effectively implement these tools, providing step-by-step instructions. Such resources offer practical applications of instruction, improving student engagement and learning outcomes.

Implementing Repeated Reading Techniques

SDI often leverages repeated reading, a strategy frequently detailed in PDF resources, to bolster reading fluency and comprehension. This technique involves students reading the same passage multiple times, aiming for increased speed and accuracy. Examples demonstrate how to track progress and set achievable goals;

Repeated reading enhances automaticity, freeing cognitive resources for comprehension. Tutorials often suggest incorporating timed readings and charting improvements. This method is particularly beneficial for struggling readers, providing a structured approach to skill development. Learning materials act as a guide, offering routines for both teacher and learner. Effective instruction, as shown in sample plans, emphasizes consistent practice and positive reinforcement.

SDI for Mathematics

SDI in mathematics, often outlined in PDF documents, focuses on adapting instruction to address specific learning barriers. Examples include breaking down complex problems into smaller, manageable steps, a technique frequently highlighted in instructional guides. These guides emphasize the importance of individualized pacing and targeted support.

Effective SDI utilizes manipulatives and visual aids to concretize abstract concepts, as demonstrated in various tutorials. Learning materials serve as a guide, providing structured routines for both teacher and student. Sample plans detail how to modify assignments and provide alternative assessment methods. This ensures all learners can access and engage with mathematical content, fostering a deeper understanding and building confidence.

Breaking Down Complex Problems

SDI strategies, often detailed in PDF resources, emphasize breaking down complex mathematical problems into smaller, sequential steps. This approach, frequently illustrated in instruction sheets, allows students to master each component before tackling the whole. Examples include providing partially completed problems or scaffolding solutions with guiding questions.

These tutorials highlight the importance of explicit instruction and modeling. Learning materials act as a guide, offering a structured pathway through challenging concepts. Teachers can utilize visual organizers and checklists to support students’ problem-solving process. This method reduces cognitive load and promotes a sense of accomplishment, fostering greater confidence and mathematical fluency.

Using Manipulatives and Visual Aids

SDI, as demonstrated in PDF examples, frequently incorporates manipulatives and visual aids to concretize abstract mathematical concepts. These tools, highlighted in instructional guides, allow students to physically interact with problems, enhancing understanding and retention. Examples include using base-ten blocks, fraction circles, or number lines.

Tutorials emphasize that visual representations support diverse learning styles. Learning materials serve as a guide, offering a tangible connection to mathematical principles. Teachers can create visual displays, diagrams, and graphic organizers to illustrate problem-solving strategies. This approach fosters engagement and provides a scaffold for students struggling with symbolic representation, ultimately improving mathematical comprehension.

SDI for Writing

SDI strategies for writing, often detailed in PDF resources, focus on scaffolding the writing process for students with diverse needs. Examples include providing sentence starters to initiate thought and structure, as well as offering graphic organizers to plan ideas before drafting. These supports, found in classroom language guides, address challenges with organization and expression.

Furthermore, assistive technology tools, outlined in user manuals, can significantly aid students. These tools might include speech-to-text software or word prediction programs. Effective instruction, as shown in tutorials, emphasizes breaking down writing tasks into smaller, manageable steps, fostering confidence and improving writing fluency.

Providing Sentence Starters

Sentence starters, frequently found within SDI PDF examples, are a powerful technique for supporting students struggling with written expression. These prompts, often simple phrases like “I believe that…” or “The most important thing is…”, provide a launching pad for thought and reduce cognitive load. They are particularly helpful for students needing structure, as highlighted in classroom language guides.

Instruction sheets demonstrate how starters can be tailored to specific assignments, guiding students toward relevant vocabulary and sentence construction. This example of scaffolding allows students to focus on content rather than mechanics, fostering independence and improving the clarity of their writing. Effective tutorials emphasize modeling their use.

Offering Assistive Technology Tools

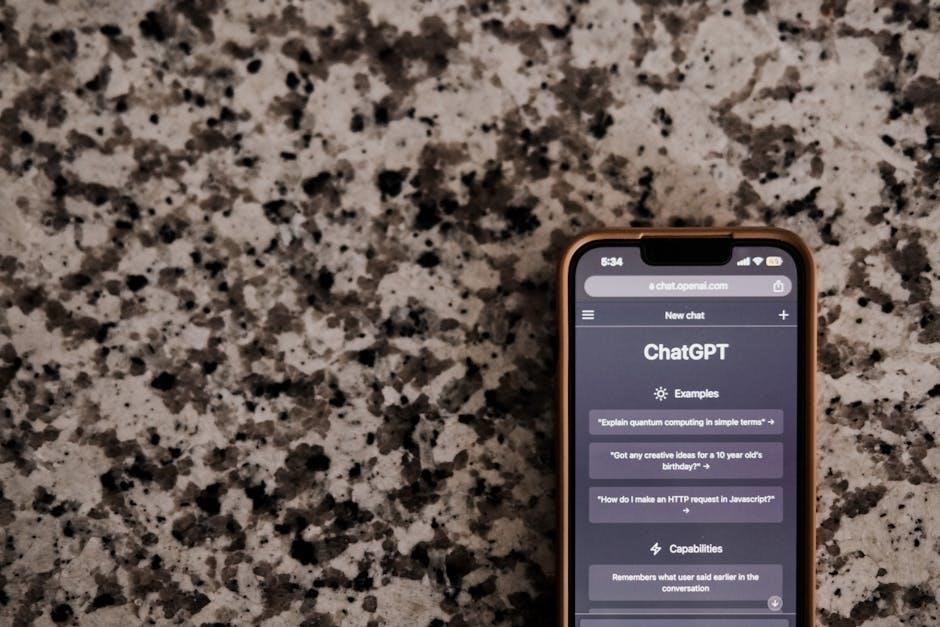

Assistive technology, detailed in many SDI PDF resources, plays a crucial role in leveling the playing field for students with diverse learning needs. Examples range from text-to-speech software, aiding reading comprehension, to speech-to-text programs, supporting writing skills. User manuals for online classroom applications often showcase integrated tools.

Instruction sheets demonstrate how to effectively implement these tools, ensuring students receive proper training and support. These technologies reduce barriers to access, allowing students to demonstrate their knowledge and participate fully. Digital tutorials provide step-by-step guidance, while classroom language guides promote inclusive tech integration;

Resources and Templates: SDI Examples PDF

Numerous online sources offer SDI examples in PDF format, including sample plans and user manuals for classroom applications, aiding educators’ implementation.

Locating Sample SDI Plans Online

Finding readily available SDI examples, often in PDF format, requires strategic online searching. Educational websites and resource hubs frequently host sample plans demonstrating individualized instruction. These documents showcase how to adapt teaching for diverse learners, aligning with IEP goals.

Specifically, exploring sites dedicated to special education resources can yield valuable templates. User manuals for online classroom applications, as highlighted, also provide concrete examples of SDI implementation within digital learning environments. Furthermore, state education agencies sometimes publish SDI guidance and sample documentation. Remember to critically evaluate any downloaded PDF, ensuring it aligns with current best practices and your students’ specific needs.

Utilizing User Manuals for Online Classroom Applications

Online classroom applications often include detailed user manuals, frequently available as PDF downloads, which can be invaluable sources of SDI examples. These manuals frequently demonstrate how to leverage the platform’s features to provide individualized support.

Look for sections detailing accessibility options, differentiation tools, and methods for adapting content presentation. The manuals are written to be intuitive, showcasing how to modify assignments or provide assistive technology integration. They often illustrate how to cater to various learning styles and needs, effectively demonstrating SDI in a digital context. Remember that while slideshow notes aren’t saved to PDF, the manual itself provides a wealth of instructional guidance.

Creating Your Own SDI Documentation

SDI documentation, like the Documentation Worksheet and Avas Skills Coded, requires outlining learning content sequences; utilize state examples from the ECO for guidance.

The Documentation Worksheet and Avas Skills Coded

Utilizing the Documentation Worksheet and Avas Skills Coded is crucial for structured SDI planning. These tools, often found as PDF resources, facilitate detailed record-keeping of individualized instruction. Trainers should print these worksheets for practical application, ensuring a consistent approach to documenting student needs and interventions.

The Avas Skills Coded system provides a framework for pinpointing specific skill deficits, informing targeted instruction; Referencing state examples, like those available on the ECO, offers concrete models for documentation. This systematic approach ensures accountability and facilitates collaboration among educators, ultimately supporting student success through well-documented SDI.

Outlining Learning Content Sequence

Effective SDI requires a carefully outlined learning content sequence, often visualized within a planning document – potentially a PDF format. This outline serves as a roadmap, breaking down complex skills into manageable steps. Authors utilize this space to establish a logical progression, ensuring students build upon prior knowledge.

For instance, a concrete example might detail sequencing tasks from simple to complex. Don’t worry about complete sentences initially; brainstorm ideas first, as suggested in practice exercises. This preparatory step, followed by a structured outline, maximizes learning potential and supports individualized instruction, aligning with SDI principles.

Digital Tools for SDI

Online tutorials and interactive instructions, often available as PDF resources, expand SDI formats; slideshow notes can be converted to PDF for accessibility.

Online Tutorials and Interactive Instructions

Online tutorials represent a significant advancement in delivering specially designed instruction (SDI), offering dynamic and engaging learning experiences. These resources, frequently available as downloadable PDF guides or embedded within classroom applications, cater to diverse learning styles and paces.

Interactive instructions, a key component of modern SDI, allow students to actively participate in the learning process, reinforcing concepts through immediate feedback and personalized support. Many platforms provide step-by-step guidance, mirroring the structure found in detailed instruction sheets.

Furthermore, the accessibility of these digital tools ensures that SDI can be implemented consistently and effectively, regardless of location or time constraints. Examples include decoding tutorials (Moats, 2006) and user manuals offering practical application.

Converting Slideshow Notes to PDF

Utilizing slideshow notes as a foundation for specially designed instruction (SDI) documentation is a practical approach, especially when creating individualized learning materials. However, it’s crucial to remember that notes saved within slideshow software may not automatically appear in downloaded PDF versions.

Therefore, educators should proactively export or copy-paste these notes into a separate document before converting to PDF format. This ensures all essential SDI details – like modified instructions or accommodation strategies – are readily available.

PDF conversion facilitates easy sharing and archiving of SDI plans, aligning with the need for clear and accessible documentation. Examples of this process can be found within user manuals for online classroom applications, demonstrating best practices for creating comprehensive learner guides.