Chainsaw Lumber Cutting: A Comprehensive Guide

This guide details essential aspects of chainsaw operation, from safety protocols and pre-cut inspections to advanced techniques․

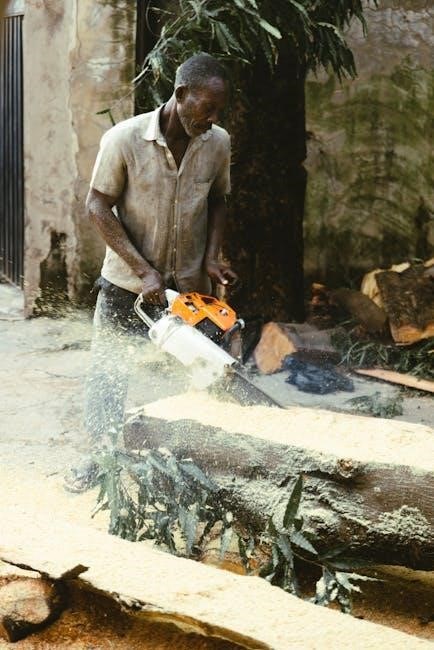

Proper chainsaw use transforms felled trees into valuable lumber,

requiring knowledge of wood grain, chain maintenance, and emergency procedures․

Understanding chainsaw types, safety gear, and cutting methods ensures efficient and safe lumber production․

Mastering these skills allows for responsible forest management and resource utilization․

Consumer Reports testing highlights models balancing speed, handling, and safety, crucial for effective lumber cutting․

Understanding Chainsaw Types for Lumber Cutting

Selecting the right chainsaw is paramount for efficient lumber cutting, and options vary significantly․ Gas-powered chainsaws deliver substantial power, ideal for felling large trees and processing substantial volumes of wood․ They are less restricted by cords, offering greater mobility, but require more maintenance and produce emissions․

Electric chainsaws, both corded and battery-powered, present quieter, cleaner alternatives․ Corded electric saws offer consistent power but limit range, while battery-powered models provide portability, though runtime is a consideration․ These are often preferred for lighter-duty tasks like limbing and bucking․

Chainsaw size is typically categorized by bar length․ Shorter bars (14-16 inches) are suitable for small-scale work, while longer bars (18-24 inches or more) are necessary for larger trees․ Consider the diameter of the wood you’ll be cutting most frequently․

Beyond power source and bar length, features like automatic chain oilers, anti-vibration systems, and chain brakes contribute to safety and ease of use․ Consumer Reports testing evaluates these aspects, helping identify models balancing performance and user-friendliness․ Ultimately, the best chainsaw depends on your specific lumber cutting needs and the scale of your projects․

Essential Chainsaw Safety Gear

Chainsaw operation demands rigorous safety precautions, beginning with appropriate personal protective equipment (PPE)․ A properly fitted helmet with a face shield or safety glasses is crucial to protect against falling debris and potential kickback․ Hearing protection, such as earmuffs, is essential due to the chainsaw’s loud engine․

Heavy-duty chainsaw chaps or pants, constructed with ballistic nylon, provide vital leg protection, significantly reducing the risk of severe injury from accidental contact with the chain․ Sturdy, steel-toed boots offer foot protection, while gloves with reinforced palms enhance grip and shield hands․

Maintaining firm footing is paramount; always be sure of your stance before initiating a cut․ Close-fitting clothing prevents snagging, and a first-aid kit should be readily accessible․ The Tulsa District U․S․ Army Corps of Engineers emphasizes comprehensive safety training, highlighting the importance of these measures․

Remember, even with the best gear, awareness and adherence to safe operating procedures are non-negotiable․ Regular inspection of PPE for damage is also vital to ensure continued protection during lumber cutting operations․

Pre-Cutting Chainsaw Inspection

A thorough pre-cutting inspection is non-negotiable for safe and efficient chainsaw operation․ Begin by verifying the chain brake functions correctly – a critical safety feature․ Inspect the chain itself for sharpness, proper tension, and damage; a dull chain increases the risk of kickback and requires sharpening or replacement․

Check the guide bar for wear, burrs, and proper lubrication․ Ensure the chain catcher is secure and undamaged, preventing chain derailment․ Examine all handles and controls, confirming they are clean, dry, and functioning smoothly․ Verify the throttle trigger and lockout mechanism operate as intended․

Fuel and oil levels must be adequate; use the correct fuel-oil mixture as specified by the manufacturer․ Inspect the anti-vibration system for integrity, as this reduces operator fatigue and improves control․ Finally, confirm the spark plug is clean and properly gapped․

Addressing any issues discovered during the inspection before starting a cut minimizes risks and maximizes performance․ Cutting wood with a well-maintained chainsaw is far more efficient and significantly safer․

Basic Chainsaw Cutting Techniques

Mastering fundamental cutting techniques is paramount for safe and productive lumber harvesting․ Always maintain a firm grip with both hands, keeping your body positioned slightly to the side of the cutting plane․ Utilize the lower portion of the bar for increased control and reduced kickback potential․

Begin cuts with a gentle plunge, allowing the chain to establish a groove before applying full pressure․ Avoid pinching the bar, which can cause kickback; use wedges to keep the cut open, especially when felling or bucking․ Employ smooth, controlled movements, letting the chainsaw do the work – avoid forcing the cut․

Understand the concept of reaction forces; the chainsaw will tend to pull in the direction of the cut․ Anticipate these forces and adjust your stance accordingly․ Never overreach or cut above shoulder height, maintaining a stable and balanced footing at all times․

Practice these techniques on smaller branches before tackling larger logs․ Consistent, deliberate cuts yield cleaner results and minimize the risk of accidents․ Remember, safety and control are always the top priorities․

Felling Small Trees: A Step-by-Step Approach

Felling even small trees demands careful planning and execution․ First, assess the tree’s lean and potential falling direction, considering wind and surrounding obstacles․ Clear a work area around the tree, establishing escape routes at 45-degree angles from the anticipated fall line․

Begin with an open-faced notch cut on the side of the tree facing the desired fall direction․ This notch should be approximately one-fifth to one-third of the tree’s diameter․ Next, make a back cut, slightly higher than the notch’s base, leaving a hinge of uncut wood․

The hinge controls the fall; ensure it’s uniform in thickness․ As the tree begins to fall, immediately retreat along your pre-planned escape route․ Avoid cutting completely through the tree, as this eliminates control․

If the tree doesn’t fall as expected, do not attempt to force it․ Re-evaluate the situation and consider using wedges or a winch to assist the process․ Prioritize safety and never risk being struck by the falling tree․

Bucking Logs: Safe and Efficient Methods

Bucking, or cutting felled logs into manageable lengths, requires a stable and secure setup․ Always ensure the log is supported to prevent pinching the chainsaw bar during the cut․ Utilize log jacks or other supports to elevate the log, creating working space․

Begin by assessing the log for internal stresses – look for bends or compression wood․ Make relief cuts on the compression side first to prevent the bar from binding․ These cuts release tension, allowing for smoother, safer bucking․

Avoid plunging cuts, which are incredibly dangerous․ Instead, bore in carefully, maintaining control of the chainsaw․ When bucking larger diameter logs, consider a three-cut method: an undercut, a top cut, and then completing the cut from the opposite side․

Never cut above mid-chest height and always maintain a firm grip on the chainsaw with both hands․ Be mindful of the log’s potential to roll or shift during the cutting process, and prioritize a clear escape path․

Limbing Techniques for Processed Lumber

Limbing, the removal of branches from a felled tree, is a hazardous task demanding focused attention․ Always work from the base of the tree towards the top, maintaining a stable stance and keeping the tree between you and the cutting path․

Utilize proper cutting techniques to avoid kickback․ Avoid cutting with the tip of the bar, and be aware of branch tension․ Smaller branches can often be removed with a single cut, but larger limbs may require notching to prevent tearing or pinching․

When limbing, support the branch with your hand or foot to prevent it from splitting and potentially causing injury․ Be especially cautious with overhead limbs, ensuring a clear working space and a safe escape route should the branch fall unexpectedly․

A sharp chain is crucial for efficient and safe limbing․ Dull chains require more force, increasing the risk of losing control․ Regularly inspect the chain and sharpen as needed․ Prioritize safety and controlled movements throughout the limbing process․

Dealing with Kickback: Prevention and Response

Kickback, a sudden, uncontrolled upward or backward movement of the chainsaw, is a leading cause of chainsaw injuries․ Understanding its causes and practicing preventative measures are paramount for safe operation․

Kickback typically occurs when the upper quadrant of the bar’s tip contacts an object, or when the wood closes in and pinches the chain․ To prevent kickback, avoid using the tip of the bar, maintain a firm grip with both hands, and keep your body positioned to the side of the cutting plane․

Always be aware of the wood’s tension and compression․ Utilize techniques like bore cutting to relieve stress and reduce the risk of pinching․ Ensure the chain is sharp and properly tensioned, as a dull chain increases the likelihood of kickback․

If kickback occurs, do not attempt to fight it․ Release the throttle and allow the saw to move․ Maintain a firm grip, but avoid resisting the force․ Immediately shut off the chainsaw and assess the situation before resuming work․

Chainsaw Chain Maintenance and Sharpening

Maintaining a sharp and properly tensioned chainsaw chain is crucial for efficient cutting, operator safety, and prolonged chain life․ A dull chain requires more force, increasing the risk of kickback and operator fatigue․

Regularly inspect the chain for damage, including cracked or missing teeth․ Clean the chain after each use, removing sawdust and debris with a brush and solvent․ Check chain tension frequently; a properly tensioned chain should be snug against the bar but still able to be pulled around by hand․

Sharpening can be done with a file, electric grinder, or by a professional․ When filing, maintain the correct filing angle and depth gauge․ Ensure all teeth are sharpened to the same length for balanced cutting․ A rounded-over tooth indicates excessive wear and necessitates chain replacement․

Cutting wood with a dull chainsaw is inefficient and dangerous․ Consistent maintenance, including cleaning, tensioning, and sharpening, will optimize performance and minimize risks during lumber cutting operations․

Understanding Wood Grain and Cutting Direction

Comprehending wood grain and its influence on cutting direction is paramount for safe and efficient lumber harvesting․ Wood isn’t uniform; grain patterns dictate how it splits and responds to the chainsaw․ Cutting with the grain generally requires less effort and produces cleaner cuts, minimizing splintering and tear-out․

Identify the grain direction before initiating any cut․ Look for the natural lines and patterns within the wood․ Avoid cutting against the grain whenever possible, especially when felling or bucking logs․ This can cause the saw to bind, increasing the risk of kickback․

Consider the tree’s lean and the prevailing wind direction when felling․ Utilize appropriate notching and back-cutting techniques to guide the tree’s fall along the desired path, working with the natural stresses within the wood․ Don’t cut anything above mid-chest height, and be mindful of log diameter relative to blade length․

Understanding these principles enhances control, reduces strain on the chainsaw, and ultimately improves the quality of the resulting lumber․

Safe Transport and Storage of Chainsaws

Proper transport and storage are crucial for maintaining chainsaw functionality and preventing accidents․ Always ensure the chainsaw is completely cooled before transport․ Engage the chain brake and utilize the scabbard to fully cover the chain, protecting it and preventing accidental contact․

When transporting in a vehicle, secure the chainsaw to prevent shifting or rolling․ A dedicated chainsaw case is ideal, but if unavailable, ensure it’s firmly restrained․ Never transport a running chainsaw, even for short distances․

For storage, choose a dry, secure location inaccessible to children and unauthorized personnel․ Store the chainsaw with the chain brake engaged and the scabbard in place․ Regularly inspect the chainsaw for any damage or leaks before storage․

Consider draining the fuel tank for long-term storage to prevent fuel degradation and carburetor issues․ A well-maintained and securely stored chainsaw is a safe and reliable tool, ready for the next lumber-cutting task․

Common Chainsaw Cutting Mistakes to Avoid

Many chainsaw mishaps stem from preventable errors․ A frequent mistake is cutting above mid-chest height, increasing instability and risk․ Never attempt to cut a tree exceeding the blade’s length in diameter – this can cause pinching and kickback․

Insufficient footing is a major hazard; always maintain a stable stance․ Neglecting to assess the tree’s lean and surrounding obstacles leads to unpredictable falls․ Using a dull chain requires excessive force, increasing fatigue and the chance of losing control․

Failing to properly maintain the chain – sharpening and tensioning – drastically reduces efficiency and safety․ Ignoring kickback prevention techniques, like keeping a firm grip and avoiding the tip of the bar, is perilous․

Rushing the process and skipping safety checks are common errors․ Prioritizing speed over caution inevitably leads to mistakes․ Remember, a slow, deliberate approach is far safer and ultimately more productive․

Choosing the Right Chainsaw Blade for Different Woods

Selecting the appropriate chainsaw blade is crucial for efficient and safe lumber cutting․ Different wood types demand specific chain designs for optimal performance․ For softwood like pine and fir, a lower rake angle (around 10 degrees) and fewer teeth per inch (TPI) – typically 3-4 – facilitate faster cutting․

Hardwoods, such as oak and maple, require blades with a higher rake angle (around 30-40 degrees) and more teeth per inch (6-8 TPI)․ This configuration provides a more aggressive bite and handles the denser material effectively․

For particularly abrasive woods or those containing significant dirt, carbide-tipped blades offer extended durability․ Rip chains, designed for cutting with the grain, excel at bucking logs into desired lengths․

Consider the wood’s condition; frozen or wet wood benefits from blades with larger gullets to efficiently clear chips․ A dull chain, regardless of type, is dangerous and inefficient – regular sharpening is paramount․

Advanced Cutting Techniques: Notching and Borer Cuts

Mastering notching and borer cuts elevates chainsaw lumber cutting precision and control․ Notching, typically used in felling, creates a directional hinge controlling the tree’s fall․ A conventional notch involves a top cut angled downwards meeting a horizontal bottom cut, forming a wedge․

Borer cuts, also known as plunge cuts, involve inserting the chainsaw tip directly into the wood, requiring extreme caution and control to prevent kickback․ These are useful for removing large sections of wood or creating access points․

Successful notching demands accurate angle estimation and consistent depth․ Borer cuts necessitate a firm grip, controlled plunge, and awareness of internal stresses within the wood․

Always prioritize safety; avoid overreaching and maintain a stable stance․ Practice these techniques on smaller logs before tackling larger trees․ Proper planning and understanding wood grain are essential for clean, accurate cuts․

Remember to never cut above mid-chest height․

Emergency Procedures and First Aid for Chainsaw Injuries

Despite rigorous safety measures, chainsaw injuries can occur․ Immediate and appropriate response is critical․ The most common injuries include cuts, lacerations, and fractures․ Prioritize scene safety – shut off the chainsaw and ensure the area is secure․

For severe bleeding, apply direct pressure to the wound with a clean cloth and elevate the injured limb․ Tourniquets should only be used as a last resort, and only if you’re trained in their application․

Suspected fractures require immobilization of the injured area․ Do not attempt to move the injured person unless absolutely necessary․

Crucially, seek professional medical attention immediately for all but the most minor injuries․ Know your location for emergency services․ A well-stocked first-aid kit, including bandages, antiseptic wipes, and a trauma dressing, is essential on any job site․

Recent training courses, like those held by the U․S․ Army Corps of Engineers, emphasize proactive safety and emergency preparedness․